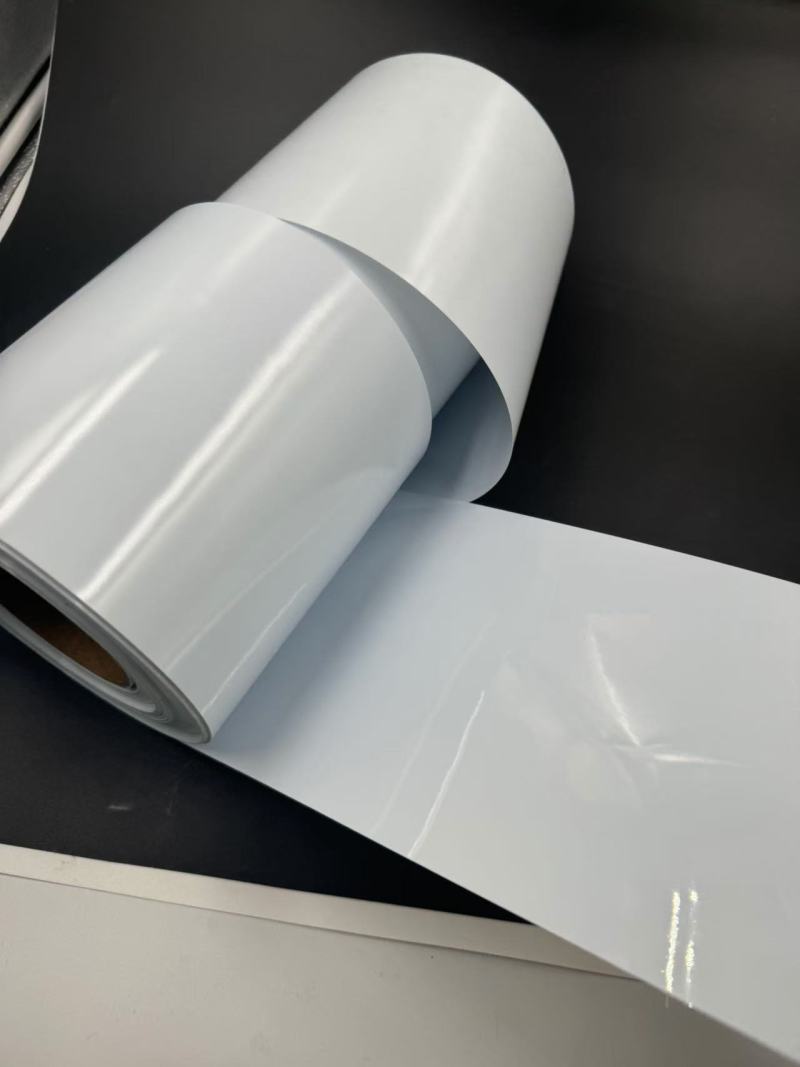

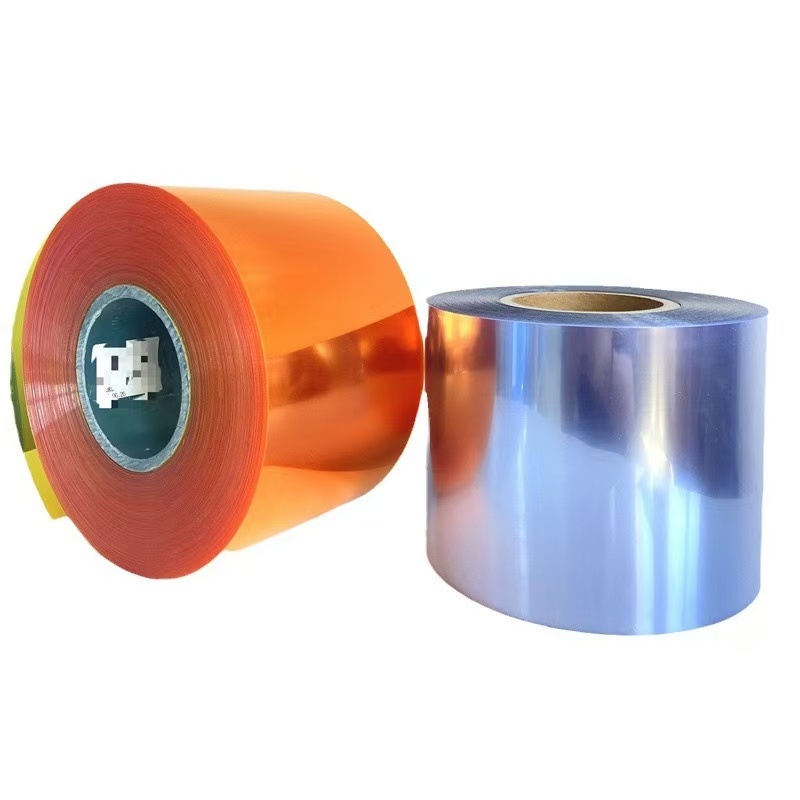

TL-PVC-0061 filme de pvc branco termoformagem embalagem farmacêutica

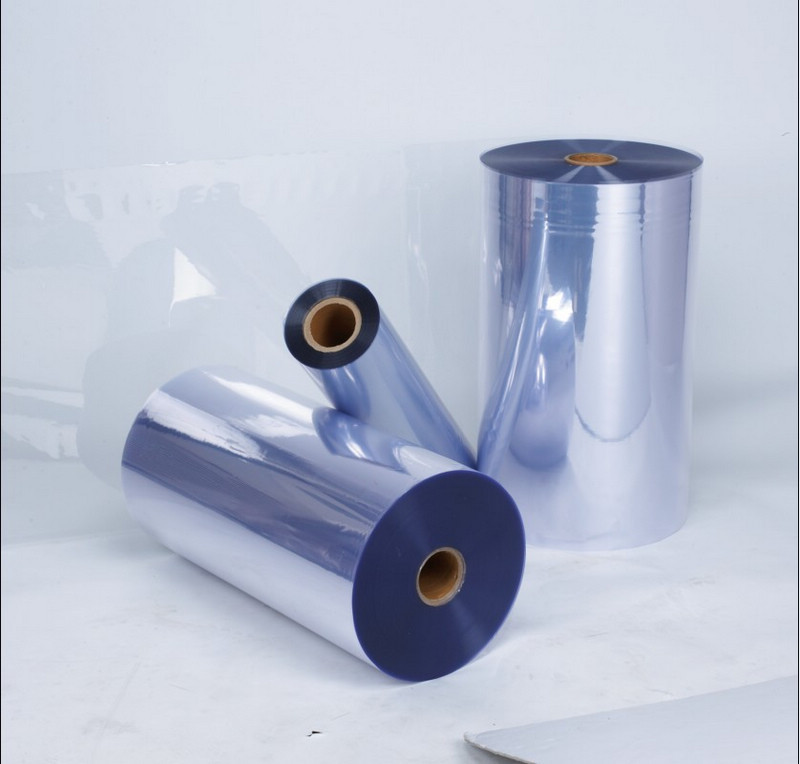

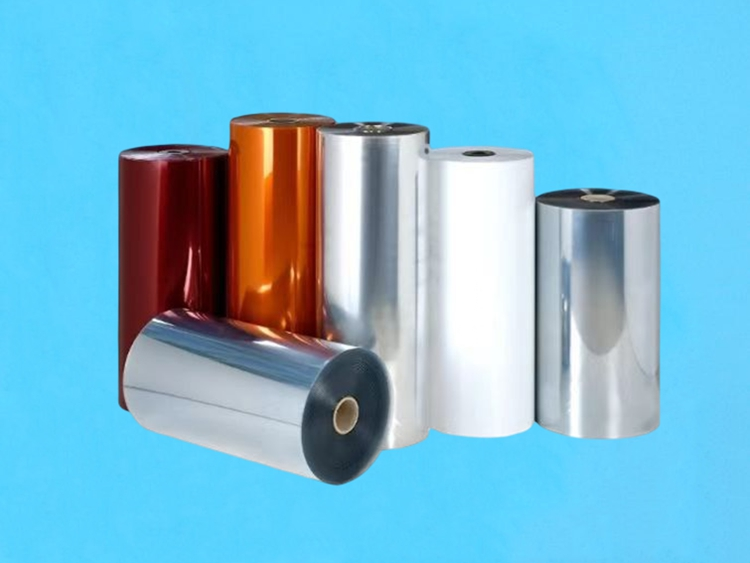

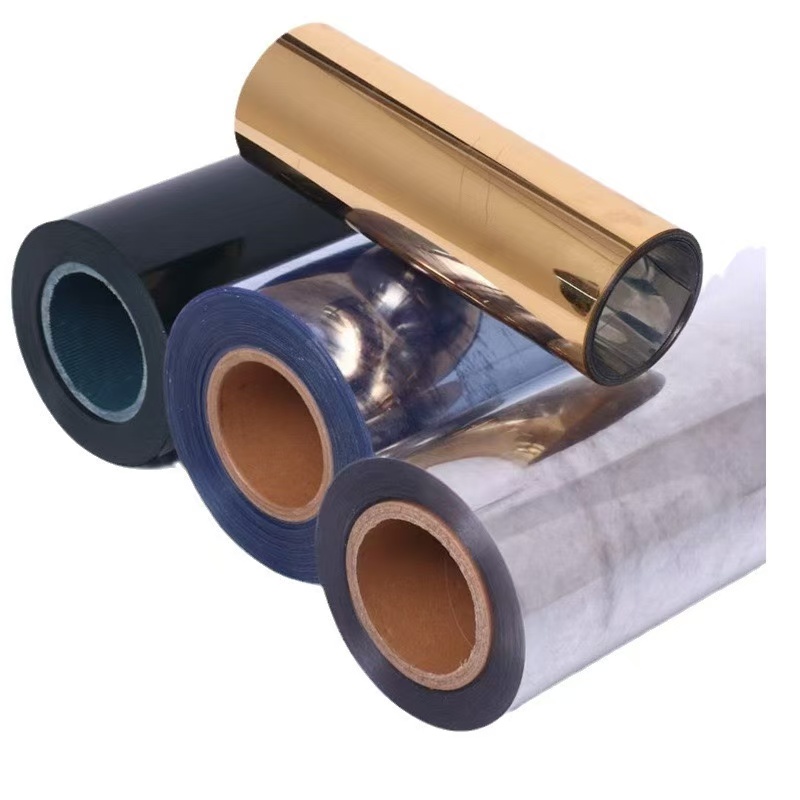

Material: ROLO DE PVC

Espessura 0,018 mm - personalização

Tamanho: 100MM-Personalização

GRAU: Filme de grau FARMACÊUTICO

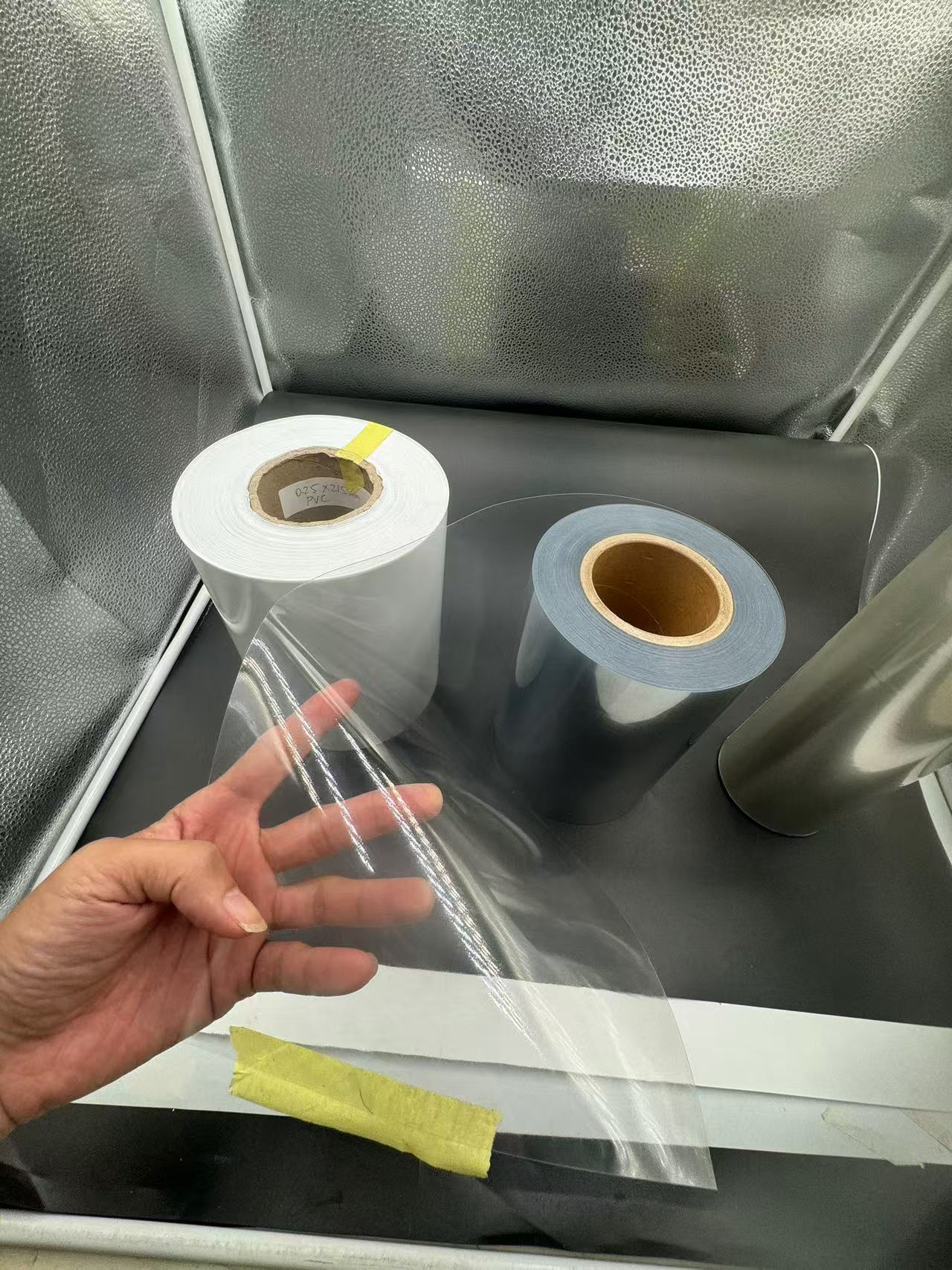

cor: branco/ personalização transparente

localização: china

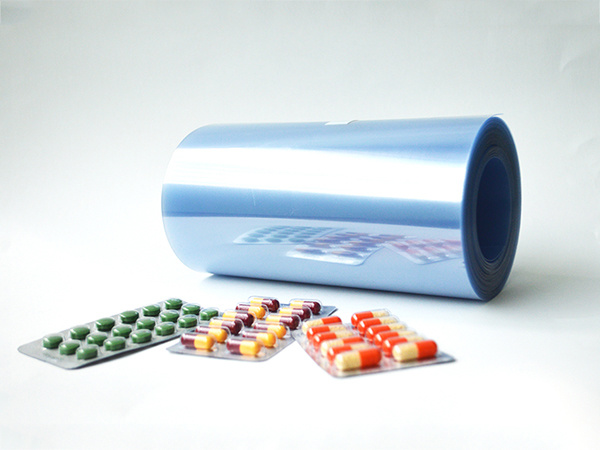

uso: para embalagem termoformadora de blister farmacêutico

- TOPLEADER

- CHINA

- 15 DIAS ÚTEIS

- 5000 toneladas/mês

- em formação

- vídeo

- baixar

《The Use of PVC Film in Pharmaceutical Packaging》

Introduction

In the field of pharmaceutical packaging, the choice of materials is crucial to ensure the safety, stability, and effectiveness of drugs. Polyvinyl chloride (PVC) film has emerged as a widely used material due to its unique properties and versatility. This article will explore the various applications of PVC film in pharmaceutical packaging, including blister packaging, composite blister packaging, and other aspects. We will discuss its advantages, challenges, and future prospects.

I. Properties of PVC Film

PVC film is a thermoplastic material that offers several desirable properties for pharmaceutical packaging.

1. Chemical Resistance

PVC film is highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. This property makes it suitable for packaging drugs that may come into contact with various substances during storage and transportation.

2. Barrier Properties

PVC film provides a good barrier against moisture, oxygen, and light. This helps to protect drugs from degradation and maintain their potency.

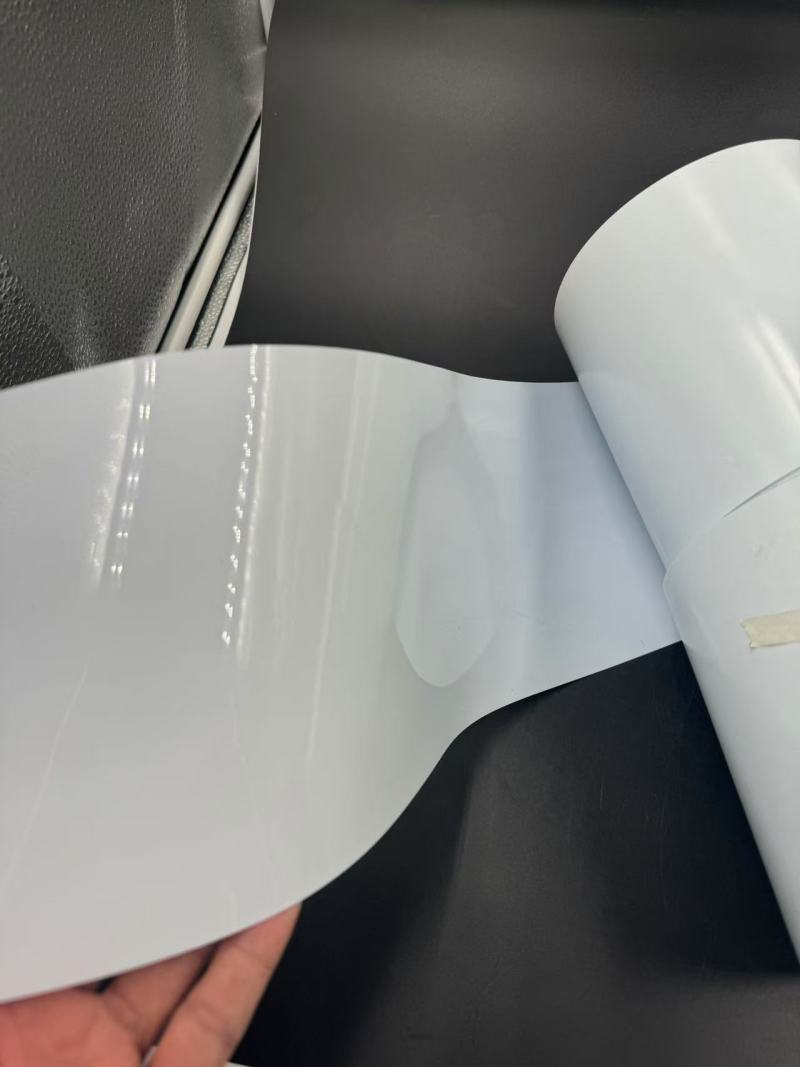

3. Flexibility and Durability

PVC film is flexible and can be easily formed into various shapes and sizes. It is also durable and can withstand handling and transportation without damage.

4. Transparency

PVC film is transparent, allowing for easy inspection of the packaged drug. This is important for ensuring the quality and integrity of the product.

5. Cost-effectiveness

PVC film is relatively inexpensive compared to other packaging materials, making it an attractive option for pharmaceutical manufacturers.

II. Applications in Blister Packaging

Blister packaging is one of the most common applications of PVC film in pharmaceutical packaging.

1. Structure of Blister Packaging

Blister packaging consists of a thermoformed PVC film that creates individual cavities for the drugs. These cavities are then sealed with a backing material, usually aluminum foil or paperboard.

2. Advantages of Blister Packaging

• Protection: Blister packaging provides excellent protection for drugs by isolating them from external factors such as moisture, oxygen, and light.

• Easy to Use: Blister packaging is convenient for patients to use as it allows for easy removal of individual doses.

• Tamper-evident: Blister packaging can be designed to be tamper-evident, ensuring the safety and integrity of the drug.

• Visual Appeal: Blister packaging is often visually appealing, which can enhance the product's marketability.

3. Manufacturing Process

The manufacturing process of blister packaging involves thermoforming the PVC film to create the cavities, filling the cavities with the drugs, and then sealing the blisters with the backing material. This process can be automated for high-volume production.

III. Applications in Composite Blister Packaging

Composite blister packaging combines the properties of different materials to provide enhanced protection and functionality.

1. Structure of Composite Blister Packaging

Composite blister packaging typically consists of a layer of PVC film, a layer of aluminum foil, and a layer of paperboard or other backing material. The layers are bonded together using adhesives or heat sealing.

2. Advantages of Composite Blister Packaging

• Improved Barrier Properties: The combination of PVC film and aluminum foil provides excellent barrier properties against moisture, oxygen, and light.

• Enhanced Strength and Durability: The addition of paperboard or other backing material gives composite blister packaging increased strength and durability.

• Customization: Composite blister packaging can be customized to meet specific packaging requirements, such as different sizes, shapes, and printing options.

3. Manufacturing Process

The manufacturing process of composite blister packaging is similar to that of blister packaging, but with the additional steps of bonding the different layers together. This process requires specialized equipment and expertise.

IV. Other Applications of PVC Film in Pharmaceutical Packaging

In addition to blister and composite blister packaging, PVC film has other applications in pharmaceutical packaging.

1. Labels and Inserts

PVC film can be used to produce labels and inserts for pharmaceutical packaging. These can be printed with important information such as drug names, dosages, and expiration dates.

2. Overwraps and Shrink Wraps

PVC film can be used to create overwraps and shrink wraps for bundles of pharmaceutical products. This provides additional protection and helps to keep the products organized.

3. Pouches and Bags

PVC film can be formed into pouches and bags for packaging drugs. These can be sealed using heat sealing or other methods and can be customized with different features such as zippers or resealable closures.

V. Challenges and Considerations

While PVC film offers many advantages for pharmaceutical packaging, there are also some challenges and considerations to keep in mind.

1. Environmental Impact

PVC film is not biodegradable and can have a negative impact on the environment. As a result, there is increasing pressure on pharmaceutical manufacturers to find more sustainable packaging solutions.

2. Regulatory Requirements

Pharmaceutical packaging is subject to strict regulatory requirements to ensure the safety and effectiveness of drugs. PVC film must meet these requirements, which can be complex and time-consuming to navigate.

3. Compatibility with Drugs

Some drugs may interact with PVC film, potentially affecting their stability and potency. Therefore, it is important to test the compatibility of drugs with PVC film before using it for packaging.

4. Cost

Although PVC film is relatively inexpensive, the cost of packaging can still be a significant factor for pharmaceutical manufacturers. In addition, the cost of specialized equipment and processes for manufacturing blister and composite blister packaging can add to the overall cost.

VI. Future Prospects

Despite the challenges, the use of PVC film in pharmaceutical packaging is expected to continue to grow in the future.

1. Technological Advancements

Advances in materials science and manufacturing technology are likely to lead to the development of new and improved PVC films with enhanced properties and performance. For example, there is ongoing research into biodegradable PVC films and films with improved barrier properties.

2. Increasing Demand for Convenience and Safety

As the demand for convenient and safe pharmaceutical packaging continues to grow, blister and composite blister packaging are likely to remain popular choices. PVC film will play an important role in meeting this demand.

3. Sustainability Initiatives

As the pharmaceutical industry becomes more environmentally conscious, there will be an increased focus on sustainable packaging solutions. While PVC film may face challenges in this area, efforts are being made to develop more sustainable alternatives or to improve the recyclability of PVC film.

Conclusion

PVC film is a versatile and widely used material in pharmaceutical packaging. Its properties of chemical resistance, barrier properties, flexibility, durability, transparency, and cost-effectiveness make it an attractive option for blister packaging, composite blister packaging, and other applications. However, there are also challenges and considerations to keep in mind, such as environmental impact, regulatory requirements, compatibility with drugs, and cost. As the pharmaceutical industry continues to evolve, technological advancements and sustainability initiatives are likely to shape the future of PVC film in pharmaceutical packaging. Despite these challenges, PVC film is expected to remain an important material in the field of pharmaceutical packaging for years to come.

Dentro de 15-20 dias após receber o pagamento...more