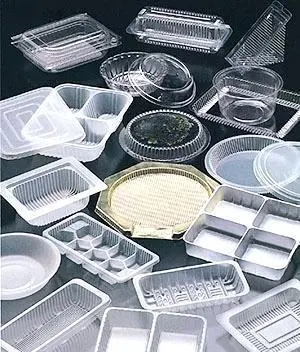

Filme PP translúcido TL-PP-337 para embalagem termoformada blister

2024-11-04 11:29Applications of Polypropylene in Thermoforming and Food Containers

Polypropylene is considered one of the most versatile plastics, having at its disposal a host of advantageous properties that make it a favorite for many applications, thermoforming, and food containers. Some of the important characteristics that make this material effective for these purposes are explained below:

Cost Effectiveness

The price of polypropylene is relatively low, making it one of the most economic materials to be used in mass production in food packaging. Because of its low price, producers can offer high-quality food containers and thermoformed products inexpensively to both producers and consumers.

Non-Toxicity

Safety is the most critical aspect when it comes to food-related uses. Since PP is non-toxic, it's safe to be used in vessels holding food without the tendency to release harmful substances to food. In this case, such characteristic makes the material quite suitable for the packaging of food storage boxes, lunch boxes, and disposable cutlery.

Wear Resistance

Its excellent abrasion resistance ensures that the products fabricated from this material can work in daily life without degradation. Food containers manufactured with PP can cope with the continuous opening and shutting, as well as cleaning, yet retaining integrity in their structure and appearance, thereby providing durability for continuous use by the consumer.

Corrosion Resistance

Since it is corrosion-resistant, PP material can be used as a food container that could come in contact with substances of all kinds. This property makes sure that it will not degrade under the presence of some acidic or alkaline foods—quality and safety will then be retained for the food stored.

Impact Resistance

Impact resistance is the very factor that makes polypropylene a very good material for successful thermoforming and food containers. In general, it ensures that drops or impacts will not cause any damage to the container and that these types of food containers can protect food inside effectively. This is important here, as many items—lunch boxes, takeout containers—are moved about a lot.

Printability

Good printability supports quality labeling and branding of food containers. The manufacturer has the ability to print minute details on logos and health nutritional information directly on the containers in which a commodity is to be filled, which makes the packaging more functional and pleasing to the human eye.

High-Temperature Resistance

High-temperature resistance makes PP suitable for heating applications. Food containers made from PP can undergo microwave heating and dishwashing without deforming or releasing harmful substances. This is of prime importance when it comes to convenience-oriented food packaging, in which reheating is a very common practice.

Conclusion:

In summary, this makes PP an excellent material for thermoforming and food containers due to its cost-effectiveness, nontoxicity, wear resistance, corrosion and impact resistance, printability, and high-temperature resistance. These properties ensure that PP products are safe, durable, and functional, making them a sure deal for food packaging and storage solutions. Consequently, PP remains one of the most applied materials in the food packaging domain since it offers several practical and economical advantages for both the manufacturer and the consumer.